Difference between revisions of "Tools/Laser Cutter"

< Tools

Jump to navigation

Jump to search

(Created page with "Hacksburg has a [https://www.camfive.com/usa/index.php/camfive-laser-cutting-and-engraving-machine-cfl-cma2416.html CAMFive CFL-CMA2416] CO2 Laser Cutter. [https://drive.goog...") |

(→Shutdown Procedure) |

||

| (13 intermediate revisions by 4 users not shown) | |||

| Line 15: | Line 15: | ||

* '''Resolution ratio:''' 4000 DPI | * '''Resolution ratio:''' 4000 DPI | ||

* '''Precision tolerance:''' 0.0079 inch. | * '''Precision tolerance:''' 0.0079 inch. | ||

| − | * '''Control Software:''' SmartCarve 4.3.21 ([https://drive.google.com/file/d/1oOoq5KYfirdXgVK2t9DpYWoIA-8tbUG7/view?usp=sharing Manual]) ([https://drive.google.com/file/d/1GhyMuBqsgTaTDnHfyIucWfycBqJGQdbi/view?usp=sharing Download]) ([https://drive.google.com/file/d/1s-td1-cxPUv1SguRa3ayP-sREhZdg7Af/view?usp=sharing Drivers]) | + | * '''Control Software:''' [https://lightburnsoftware.com/ Lightburn] |

| − | ** According to support, select 5th controller when prompted | + | ** Free trial available, discount for Hacksburg members |

| − | ** Current version requires key dongle, previous version has demo available ([http://www.yueminglaser.com/YMlaserfiles/YMfiles/Software/install/SmartCarve4/SmartcarveInstall4.3.exe Download]) | + | ** Previously used SmartCarve 4.3.21 ([https://drive.google.com/file/d/1oOoq5KYfirdXgVK2t9DpYWoIA-8tbUG7/view?usp=sharing Manual]) ([https://drive.google.com/file/d/1GhyMuBqsgTaTDnHfyIucWfycBqJGQdbi/view?usp=sharing Download]) ([https://drive.google.com/file/d/1s-td1-cxPUv1SguRa3ayP-sREhZdg7Af/view?usp=sharing Drivers]) |

| + | *** According to support, select 5th controller when prompted | ||

| + | *** Current version requires key dongle, previous version has demo available ([http://www.yueminglaser.com/YMlaserfiles/YMfiles/Software/install/SmartCarve4/SmartcarveInstall4.3.exe Download]) | ||

* '''Accessories:''' Compressed air assist, red dot pointer, refrigerated water chiller, water pump, fume exhaust | * '''Accessories:''' Compressed air assist, red dot pointer, refrigerated water chiller, water pump, fume exhaust | ||

| Line 36: | Line 38: | ||

* Excessive smoke/debris will damage the lens - Stop work if you notice unusual amounts | * Excessive smoke/debris will damage the lens - Stop work if you notice unusual amounts | ||

* '''The laser beam to the eye can cause permanent retinal damage and even blindness; on the skin it can cause severe burns.''' | * '''The laser beam to the eye can cause permanent retinal damage and even blindness; on the skin it can cause severe burns.''' | ||

| + | |||

| + | === Material Safety === | ||

| + | * TO DO: better list, but for now, make sure you have looked up your specific material as being laser cutter compatible. | ||

| + | ** [http://discourse.fablabelpaso.org/t/choosing-the-right-type-of-plywood/45 Tips for Plywood] | ||

| + | * '''NEVER''' chlorinated plastics (PVC, CPVC, vinyl, etc.) | ||

| + | * '''NEVER''' chrome tanned leathers | ||

| + | * '''NEVER''' unknown plastics; if you're not sure what it is, it doesn't go in the machine | ||

| + | * '''AVOID''' polycarbonate plastics (Lexan) | ||

| + | * '''AVOID''' high-density polyethelyne (HDPE) | ||

| + | * '''AVOID''' oil-tanned or dyed leathers | ||

| + | * '''AVOID''' unknown plywoods with unknown glues | ||

| + | * '''AVOID''' metals except in extremly thin films, make sure all layers are laser cutter safe | ||

| + | * Suggested for cutting and engraving: | ||

| + | ** Acrylic plastic (cell-cast is better than extruded, but either will work) | ||

| + | ** PMMA, also known as acrylic or acrylic glass as well as by the trade names Crylux, Plexiglas, Acrylite, Lucite, and Perspex | ||

| + | ** Solid woods | ||

| + | ** Paper, cardstock, cardboard, etc. | ||

| + | ** Foam-core | ||

| + | * Suggested for engraving or frosting only: | ||

| + | ** Glass (ordinary cheap (soda-lime, untempered) glass is best) | ||

| + | ** Stone (flat, polished; granite or limestone supposedly are good choices) | ||

==Cutting Parameters== | ==Cutting Parameters== | ||

A running list of cutting parameters is maintained in the [[Tool/Laser_Cutter/Cutting Parameters|Cutting Parameters]] article. | A running list of cutting parameters is maintained in the [[Tool/Laser_Cutter/Cutting Parameters|Cutting Parameters]] article. | ||

| + | |||

| + | A Lightburn materials file for the 80W laser can be downloaded here: [[Media:HacksburgMaterials.clb]]. The most up to date version will be on the laser cutter PC. | ||

| + | |||

| + | ==Lightburn Device Setup== | ||

| + | |||

| + | Laser cutter device settings in Lightburn. | ||

| + | You will see a device setup wizard on Lightburn's first launch. | ||

| + | You can also edit and add new devices on the bottom right by pressing the "Devices" button | ||

| + | |||

| + | * Laser/Controler: Ruida | ||

| + | * Connection interface: Serial/USB | ||

| + | * Name: Hacksburg (or whatever you wish) | ||

| + | * Working area dimentions: 600mm x 400mm | ||

| + | * Origin: Rear Right | ||

==Startup and Operation Procedure== | ==Startup and Operation Procedure== | ||

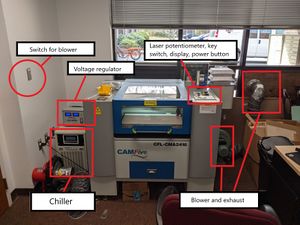

| + | [[File:Laser component location.jpg|thumb|Overview of component locations]] | ||

# Check your materials before approaching cutter | # Check your materials before approaching cutter | ||

| − | #* | + | #* See Materials Safety section above |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

# Check cutter and accessories for obvious damage or malfunction - if something looks damaged stop and contact [mailto:board@hacksburg.org board@hacksburg.org] | # Check cutter and accessories for obvious damage or malfunction - if something looks damaged stop and contact [mailto:board@hacksburg.org board@hacksburg.org] | ||

# PC monitor on if not already (push button under bottom edge to right of center) | # PC monitor on if not already (push button under bottom edge to right of center) | ||

| − | # PC on if not already ( | + | # PC on if not already (need to open hinged door on front of tower) |

| − | # Log into Hacksburg account on PC | + | # Log into Hacksburg account on PC (no password) |

| − | # Start | + | # Start LightBurn software on PC |

| − | #* | + | #* Red dragon-shaped icon on desktop or task bar |

# Create or load, import, adjust files etc. | # Create or load, import, adjust files etc. | ||

| − | # | + | #* See documentation elsewhere (pending) on compatible file formats, layer standards, etc. |

| − | + | #* You will need to set the intensity and speed for any layer you use. See [[Tools/Laser_Cutter/Cutting Parameters|Cutting Parameters]] page for more info. | |

| − | #* You will need to | + | #** Note that the software appears to process layers in numerical order. Layers should be configured so that the cuts will happen after the engraving. |

| − | + | #** Depending on the last user, some layers may start turned off. Click the toggle under the "Output" column to turn them back on (and, if needed, the toggle under "Show". The "Air" toggle has no effect). | |

| − | #** Note that the | + | #** Unless you are sure what you are doing, Positioning Mode in LightBurn should be set to "Absolute Coordinates", and the upper right of your file should be aligned with the upper right of the work area (and the 0,0 of the laser cutter) |

| − | + | # Ensure that the water in the chiller fully covers the metal coil (the lid for the water level is underneath the power conditioner on the top of the chiller). If not, top it up from the jug of '''distilled''' water (usually found under the table) | |

| − | #** Depending on the last user, some layers may start turned off. | ||

| − | #** Unless you are sure what you are doing, Positioning Mode in | ||

| − | # Ensure that the water in the chiller fully covers the metal coil. If not, top it up from the jug of '''distilled''' water (usually found under the table) | ||

# Rotate laser potentiometer to 0 (fully CCW) | # Rotate laser potentiometer to 0 (fully CCW) | ||

| − | + | [[File:Laser control potentiometer.jpg|thumb|Location of potentiometer]] | |

| − | # CamFive voltage regulator on (flip up red switch on regulator, | + | # <li value="10"> CamFive voltage regulator on (flip up red switch on regulator, box on the back left corner of laser cutter) </li> |

| − | # Check that | + | # Check that regulator output power bar is on |

#* Push in blue button if red light is not lit | #* Push in blue button if red light is not lit | ||

| − | + | [[File:Laser power strip button.jpg|thumb|Power Strip]] | |

| − | # | + | # <li value="12"> Laser main power on (flip up blue power switch on right side of main laser unit) </li> |

| − | # | + | # Turn on water chiller (bottom red rocker switch right side of laser cutter) |

| − | #* Check that Set Point is | + | #* Press power button to lower right of screen on chiller to put into Run mode |

| + | #* Check that Set Point is 21º C and Temp Diff is 0.5º C | ||

#* If Water Temp is greater than about 24º C, wait until chiller has brought it down some | #* If Water Temp is greater than about 24º C, wait until chiller has brought it down some | ||

| − | + | [[File:Laser control switches.jpg|thumb|Laser control switches]] | |

| − | + | # <li value="14"> Insert laser key and turn 1/4 turn CW | |

| − | |||

| − | |||

| − | # Insert laser key and turn 1/4 turn CW | ||

# Wait for laser internal system to boot | # Wait for laser internal system to boot | ||

#* White internal work area light and red dot pointer should be on | #* White internal work area light and red dot pointer should be on | ||

#** Note: The red dot alignment pointer, while technically a laser, is not what actually does the cutting and is harmless.References to "laser" in this document refer to the main 80W IR (invisble) laser, not the red dot. | #** Note: The red dot alignment pointer, while technically a laser, is not what actually does the cutting and is harmless.References to "laser" in this document refer to the main 80W IR (invisble) laser, not the red dot. | ||

# Check laser display screen for any error messages or problems | # Check laser display screen for any error messages or problems | ||

| − | # Lift cover and load your media; secure if needed | + | # Lift cover and load your media; secure if needed |

#* The usable (writable) area is 600 mm x 400 mm, or about 24" x 16" | #* The usable (writable) area is 600 mm x 400 mm, or about 24" x 16" | ||

#* The honeycomb part of the bed is about 25 3/8" x 17 1/4" | #* The honeycomb part of the bed is about 25 3/8" x 17 1/4" | ||

| − | #* If everything is set correctly, the " | + | #* If everything is set correctly, the "Absolute Coordinates" 0,0 point is in the upper right of the usable area |

#* Approximate offset of 0,0 from the upper right edge of the honeycomb is 22.25 mm from right, 27.75 mm from top | #* Approximate offset of 0,0 from the upper right edge of the honeycomb is 22.25 mm from right, 27.75 mm from top | ||

| − | #* Check the | + | #* Check the yellow Laser Guides bin for jigs; use the ones labeled 22.5 mm Right and 28 mm Top as needed |

# Turn on Air Pump (middle red switch on right side of main laser unit) | # Turn on Air Pump (middle red switch on right side of main laser unit) | ||

# Adjust laser vertical clearance and focus | # Adjust laser vertical clearance and focus | ||

| + | #* Use the laser controls to move the laser head over the middle of the material. Ensure that the tip will not collide with the material, raise if needed. | ||

#* Find "Laser Vertical Calibration Guide" (thick clear tile that should be in the blue Laser Guides bin, on or near the laser cutter) | #* Find "Laser Vertical Calibration Guide" (thick clear tile that should be in the blue Laser Guides bin, on or near the laser cutter) | ||

#* Place block on material, slide to near laser output nozzle | #* Place block on material, slide to near laser output nozzle | ||

#* While supporting the lower head with one hand, loosen the brass vertical adjust knob (turn CCW to loosen) | #* While supporting the lower head with one hand, loosen the brass vertical adjust knob (turn CCW to loosen) | ||

| − | #** Note: This is the horizontal knurled brass knob that sticks out straight to the right | + | #** Note: This is the horizontal knurled brass knob that sticks out straight to the right, '''with a green rubber cover''' |

| − | #** | + | #** '''Do not touch any other knobs on the laser head, as this may change the alignment''' |

#* Slide calibration block under nozzle (while on top of your media) | #* Slide calibration block under nozzle (while on top of your media) | ||

#* Gently lower the nozzle until it is nearly but not quite touching the calibration block | #* Gently lower the nozzle until it is nearly but not quite touching the calibration block | ||

#* You should hear the sound of the compressed air hissing louder, but not low enough that it stops | #* You should hear the sound of the compressed air hissing louder, but not low enough that it stops | ||

| − | #* Tighten the brass vertical adjust knob (turn CW to tighten, finger tight only.Do not put much force into it.) | + | #* Tighten the brass vertical adjust knob (turn CW to tighten, finger tight only. Do not put much force into it.) |

#* Note: the proper distance is 5 mm to 6 mm from the bottom of the nozzle to the closest part of the media for most purposes | #* Note: the proper distance is 5 mm to 6 mm from the bottom of the nozzle to the closest part of the media for most purposes | ||

#* For certain sorts of area-fill engraving or frosting, it may be desirable to raise the laser somewhat above the focus area to increase the spot size. Research into this is a work in progress. | #* For certain sorts of area-fill engraving or frosting, it may be desirable to raise the laser somewhat above the focus area to increase the spot size. Research into this is a work in progress. | ||

| Line 119: | Line 135: | ||

#* Check that laser cover is fully closed | #* Check that laser cover is fully closed | ||

#* Check that laser power is still Off (white button is up and not illuminated) | #* Check that laser power is still Off (white button is up and not illuminated) | ||

| − | #* In | + | #* In the software, check that positioning mode is set to Absolute Coordinates (unless you are deliberately using Current Position mode) |

| − | #* In | + | #* In the software, press "Frame" button under the laser tab |

| − | #* Watch the laser | + | #* Watch the laser trace the bounding box of the job. Note that the red laser pointer is only an approximation of where the invisible IR cutting laser will go. |

| − | # | + | # Fume filter on if not already (cordless remote stored on top of laser cutter) |

| − | |||

| − | |||

| − | |||

# When ready, push white circular Laser Power On/Off button in (lights up white) | # When ready, push white circular Laser Power On/Off button in (lights up white) | ||

| − | # Adjust laser power potentiometer to desired power | + | # Adjust laser power potentiometer (knob labeled "Laser 1") to desired power |

| − | #* Current recommendation is to program your settings with the | + | #* Current recommendation is to program your settings with the potentiometer at 100%, so that you can use laser full power and most reliable repeatability. |

| − | + | #* Relationship between the power settings in Lightburn and the dial seems largely multiplicative. e.g. 50% in software and 50% on potentiometer approximately equals 25% power | |

| − | #* | + | #* A minimum of approximately 20% power is required for the laser to turn on |

| − | # Before clicking start, double check that chiller, air-pump, and | + | # Before clicking start, double check that chiller, air-pump, and fume filter are running, window is open, and laser lid is closed |

| − | # In | + | # In the laser software, press Start button (under "Laser" tab in Lightburn, bottom right) |

| − | # Watch your job progress through the tinted front or top window of the laser cutter.If there are problems, use the | + | # Watch your job progress through the tinted front or top window of the laser cutter. If there are problems, use the Pause or Stop buttons in the laser cutter software as a first choice, the Start/Pause button on the laser control panel as a second choice. If the Emergency Stop button is used, you should reboot the unit after correcting the problem. |

| − | #* In case of minor flare-ups, once the laser is stopped use the green spray bottle of water.Try not to get water onto any of the optical or mechanical components, and make sure everything is fully dry before continuing. | + | #* In case of minor fire flare-ups, once the laser is stopped use the green spray bottle of water .Try not to get water onto any of the optical or mechanical components, and make sure everything is fully dry before continuing. |

==Shutdown Procedure== | ==Shutdown Procedure== | ||

# Once final cut has completed and laser has stopped, press the white circular Laser Power On/Off button to deactivate the beam (switch back light should turn off) | # Once final cut has completed and laser has stopped, press the white circular Laser Power On/Off button to deactivate the beam (switch back light should turn off) | ||

# If your job produced some smoke or fumes, wait a minute for them to clear. | # If your job produced some smoke or fumes, wait a minute for them to clear. | ||

| − | #* It may be | + | #* It may be helpful to lift the lid just slightly to suck in room air from the front over your media. |

# Lift cover and unload your media; remove any debris remaining from cutting; close cover | # Lift cover and unload your media; remove any debris remaining from cutting; close cover | ||

| − | # If you will be using it again soon, you can temporarily turn the exhaust fan | + | # If you will be using it again soon, you can temporarily turn the exhaust fan off (cordless remote on top of laser cutter) to reduce background noise while you edit. Remember to turn the exhaust fan back on before starting again! |

# When done for the day: | # When done for the day: | ||

| − | # Remove and return guides, alignment blocks, jigs, etc. to the | + | # Remove and return guides, alignment blocks, jigs, etc. to the yellow Laser Guides bin or other proper storage location |

# Rotate laser potentiometer to 0 (fully CCW) | # Rotate laser potentiometer to 0 (fully CCW) | ||

| − | # Turn off | + | # Turn off air pump (middle red rocker switch right side of laser cutter) |

| + | # Turn off fume filter (cordless remote on top of main laser unit) | ||

| + | #* If there is a strong smell in the room, allow the fume filter to run longer | ||

| + | # Put the water chiller in standby mode (press the power button on the front panel, screen should read "Standby") | ||

| + | #* '''The chiller must be put in standby before powering off or permanent damage may occur''' | ||

| + | # Turn off water chiller (bottom red rocker switch right side of laser cutter) | ||

# Turn off laser unit by rotating key 1/4 turn CCW); remove laser key and return to storage location | # Turn off laser unit by rotating key 1/4 turn CCW); remove laser key and return to storage location | ||

# Laser main power off (flip down blue power switch on right side of unit) | # Laser main power off (flip down blue power switch on right side of unit) | ||

# CamFive voltage regulator off (flip down red switch on front of voltage regulator) | # CamFive voltage regulator off (flip down red switch on front of voltage regulator) | ||

| − | |||

| − | |||

| − | |||

# Make sure any files are cleaned off the PC, or put in your userfiles folder under Hacksburg's "My Documents" | # Make sure any files are cleaned off the PC, or put in your userfiles folder under Hacksburg's "My Documents" | ||

#* e.g. C:\Users\Hacksburg\My Documents\userfiles\//yourname// | #* e.g. C:\Users\Hacksburg\My Documents\userfiles\//yourname// | ||

Latest revision as of 14:54, 11 February 2024

Hacksburg has a CAMFive CFL-CMA2416 CO2 Laser Cutter.

Contents

Specifications

- Bed size: 24 in x 16 in honeycomb worktable, rear pass-through, material up to 3/4" thick

- Actual working area is 600 mm x 400 mm

- Laser Power: 80 Watts (80W Pro tube)

- Engraving speed: 0-40 inch/s (0-1016 mm/s)

- (May be limited to 400 mm/s with current setup)

- Max cutting speed: 0-23 inch/s (0-584 mm/s)

- (May be limited to 400 mm/s with current setup)

- Resolution ratio: 4000 DPI

- Precision tolerance: 0.0079 inch.

- Control Software: Lightburn

- Accessories: Compressed air assist, red dot pointer, refrigerated water chiller, water pump, fume exhaust

Safety Info

| Potential Hazards: Burns, Eye Damage, Fire, Toxic fumes |

|---|

- Only cut known,acceptable materials (untreated/unstained)

- Certain materials give off extremely toxic fumes - For example, PVC, Vinyl, Chrome-tanned leather, and several other materials give off chlorine gas which can cause severe long-term health effects.

- Always turn off laser before opening lid

- Wear safety glasses if viewing laser through gaps in side of lid

- Pause/Stop cut immediately if you see flames; if flame doesn't go out, use the spray bottle and then fire extinguisher

- STOP ALL WORK IMMEDIATELY and ask for assistance if you SMELL, HEAR, or SEE anything unusual

- Ensure all people and objects are out of the way of the laser head’s homing motion when you power on the machine

- Check that all accessories turn on when you power on the machine

- Excessive smoke/debris will damage the lens - Stop work if you notice unusual amounts

- The laser beam to the eye can cause permanent retinal damage and even blindness; on the skin it can cause severe burns.

Material Safety

- TO DO: better list, but for now, make sure you have looked up your specific material as being laser cutter compatible.

- NEVER chlorinated plastics (PVC, CPVC, vinyl, etc.)

- NEVER chrome tanned leathers

- NEVER unknown plastics; if you're not sure what it is, it doesn't go in the machine

- AVOID polycarbonate plastics (Lexan)

- AVOID high-density polyethelyne (HDPE)

- AVOID oil-tanned or dyed leathers

- AVOID unknown plywoods with unknown glues

- AVOID metals except in extremly thin films, make sure all layers are laser cutter safe

- Suggested for cutting and engraving:

- Acrylic plastic (cell-cast is better than extruded, but either will work)

- PMMA, also known as acrylic or acrylic glass as well as by the trade names Crylux, Plexiglas, Acrylite, Lucite, and Perspex

- Solid woods

- Paper, cardstock, cardboard, etc.

- Foam-core

- Suggested for engraving or frosting only:

- Glass (ordinary cheap (soda-lime, untempered) glass is best)

- Stone (flat, polished; granite or limestone supposedly are good choices)

Cutting Parameters

A running list of cutting parameters is maintained in the Cutting Parameters article.

A Lightburn materials file for the 80W laser can be downloaded here: Media:HacksburgMaterials.clb. The most up to date version will be on the laser cutter PC.

Lightburn Device Setup

Laser cutter device settings in Lightburn. You will see a device setup wizard on Lightburn's first launch. You can also edit and add new devices on the bottom right by pressing the "Devices" button

- Laser/Controler: Ruida

- Connection interface: Serial/USB

- Name: Hacksburg (or whatever you wish)

- Working area dimentions: 600mm x 400mm

- Origin: Rear Right

Startup and Operation Procedure

- Check your materials before approaching cutter

- See Materials Safety section above

- Check cutter and accessories for obvious damage or malfunction - if something looks damaged stop and contact board@hacksburg.org

- PC monitor on if not already (push button under bottom edge to right of center)

- PC on if not already (need to open hinged door on front of tower)

- Log into Hacksburg account on PC (no password)

- Start LightBurn software on PC

- Red dragon-shaped icon on desktop or task bar

- Create or load, import, adjust files etc.

- See documentation elsewhere (pending) on compatible file formats, layer standards, etc.

- You will need to set the intensity and speed for any layer you use. See Cutting Parameters page for more info.

- Note that the software appears to process layers in numerical order. Layers should be configured so that the cuts will happen after the engraving.

- Depending on the last user, some layers may start turned off. Click the toggle under the "Output" column to turn them back on (and, if needed, the toggle under "Show". The "Air" toggle has no effect).

- Unless you are sure what you are doing, Positioning Mode in LightBurn should be set to "Absolute Coordinates", and the upper right of your file should be aligned with the upper right of the work area (and the 0,0 of the laser cutter)

- Ensure that the water in the chiller fully covers the metal coil (the lid for the water level is underneath the power conditioner on the top of the chiller). If not, top it up from the jug of distilled water (usually found under the table)

- Rotate laser potentiometer to 0 (fully CCW)

- CamFive voltage regulator on (flip up red switch on regulator, box on the back left corner of laser cutter)

- Check that regulator output power bar is on

- Push in blue button if red light is not lit

- Laser main power on (flip up blue power switch on right side of main laser unit)

- Turn on water chiller (bottom red rocker switch right side of laser cutter)

- Press power button to lower right of screen on chiller to put into Run mode

- Check that Set Point is 21º C and Temp Diff is 0.5º C

- If Water Temp is greater than about 24º C, wait until chiller has brought it down some

- Insert laser key and turn 1/4 turn CW

- Wait for laser internal system to boot

- White internal work area light and red dot pointer should be on

- Note: The red dot alignment pointer, while technically a laser, is not what actually does the cutting and is harmless.References to "laser" in this document refer to the main 80W IR (invisble) laser, not the red dot.

- White internal work area light and red dot pointer should be on

- Check laser display screen for any error messages or problems

- Lift cover and load your media; secure if needed

- The usable (writable) area is 600 mm x 400 mm, or about 24" x 16"

- The honeycomb part of the bed is about 25 3/8" x 17 1/4"

- If everything is set correctly, the "Absolute Coordinates" 0,0 point is in the upper right of the usable area

- Approximate offset of 0,0 from the upper right edge of the honeycomb is 22.25 mm from right, 27.75 mm from top

- Check the yellow Laser Guides bin for jigs; use the ones labeled 22.5 mm Right and 28 mm Top as needed

- Turn on Air Pump (middle red switch on right side of main laser unit)

- Adjust laser vertical clearance and focus

- Use the laser controls to move the laser head over the middle of the material. Ensure that the tip will not collide with the material, raise if needed.

- Find "Laser Vertical Calibration Guide" (thick clear tile that should be in the blue Laser Guides bin, on or near the laser cutter)

- Place block on material, slide to near laser output nozzle

- While supporting the lower head with one hand, loosen the brass vertical adjust knob (turn CCW to loosen)

- Note: This is the horizontal knurled brass knob that sticks out straight to the right, with a green rubber cover

- Do not touch any other knobs on the laser head, as this may change the alignment

- Slide calibration block under nozzle (while on top of your media)

- Gently lower the nozzle until it is nearly but not quite touching the calibration block

- You should hear the sound of the compressed air hissing louder, but not low enough that it stops

- Tighten the brass vertical adjust knob (turn CW to tighten, finger tight only. Do not put much force into it.)

- Note: the proper distance is 5 mm to 6 mm from the bottom of the nozzle to the closest part of the media for most purposes

- For certain sorts of area-fill engraving or frosting, it may be desirable to raise the laser somewhat above the focus area to increase the spot size. Research into this is a work in progress.

- TO DO: Cut a better primary calibration block and a second one for defocused engraving

- Test job for origin, size, location, interference, etc. without laser power

- Check that laser cover is fully closed

- Check that laser power is still Off (white button is up and not illuminated)

- In the software, check that positioning mode is set to Absolute Coordinates (unless you are deliberately using Current Position mode)

- In the software, press "Frame" button under the laser tab

- Watch the laser trace the bounding box of the job. Note that the red laser pointer is only an approximation of where the invisible IR cutting laser will go.

- Fume filter on if not already (cordless remote stored on top of laser cutter)

- When ready, push white circular Laser Power On/Off button in (lights up white)

- Adjust laser power potentiometer (knob labeled "Laser 1") to desired power

- Current recommendation is to program your settings with the potentiometer at 100%, so that you can use laser full power and most reliable repeatability.

- Relationship between the power settings in Lightburn and the dial seems largely multiplicative. e.g. 50% in software and 50% on potentiometer approximately equals 25% power

- A minimum of approximately 20% power is required for the laser to turn on

- Before clicking start, double check that chiller, air-pump, and fume filter are running, window is open, and laser lid is closed

- In the laser software, press Start button (under "Laser" tab in Lightburn, bottom right)

- Watch your job progress through the tinted front or top window of the laser cutter. If there are problems, use the Pause or Stop buttons in the laser cutter software as a first choice, the Start/Pause button on the laser control panel as a second choice. If the Emergency Stop button is used, you should reboot the unit after correcting the problem.

- In case of minor fire flare-ups, once the laser is stopped use the green spray bottle of water .Try not to get water onto any of the optical or mechanical components, and make sure everything is fully dry before continuing.

Shutdown Procedure

- Once final cut has completed and laser has stopped, press the white circular Laser Power On/Off button to deactivate the beam (switch back light should turn off)

- If your job produced some smoke or fumes, wait a minute for them to clear.

- It may be helpful to lift the lid just slightly to suck in room air from the front over your media.

- Lift cover and unload your media; remove any debris remaining from cutting; close cover

- If you will be using it again soon, you can temporarily turn the exhaust fan off (cordless remote on top of laser cutter) to reduce background noise while you edit. Remember to turn the exhaust fan back on before starting again!

- When done for the day:

- Remove and return guides, alignment blocks, jigs, etc. to the yellow Laser Guides bin or other proper storage location

- Rotate laser potentiometer to 0 (fully CCW)

- Turn off air pump (middle red rocker switch right side of laser cutter)

- Turn off fume filter (cordless remote on top of main laser unit)

- If there is a strong smell in the room, allow the fume filter to run longer

- Put the water chiller in standby mode (press the power button on the front panel, screen should read "Standby")

- The chiller must be put in standby before powering off or permanent damage may occur

- Turn off water chiller (bottom red rocker switch right side of laser cutter)

- Turn off laser unit by rotating key 1/4 turn CCW); remove laser key and return to storage location

- Laser main power off (flip down blue power switch on right side of unit)

- CamFive voltage regulator off (flip down red switch on front of voltage regulator)

- Make sure any files are cleaned off the PC, or put in your userfiles folder under Hacksburg's "My Documents"

- e.g. C:\Users\Hacksburg\My Documents\userfiles\//yourname//