Tools/Onefinity: Difference between revisions

No edit summary |

|||

| (5 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

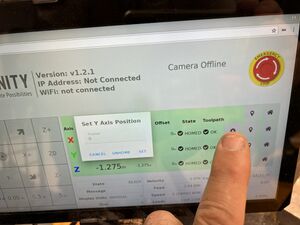

The Onefinity is a CNC router. It is used for precision-carving of wood, acrylic, soft metals and other materials. Onefinity generously discounted this unit through a Makerspace support program they offered to Hacksburg. A CNC router processes "G-code" to tell it where in X,Y,Z space to go, how fast, and in what order. The essence of the process is to first create a model or design (CAD, STL, Thingiverse, Inkscape), then convert that design into G-code. The G-code is transfered to the router controller on a thumb drive, and the router controller executes that code to completion. | The Onefinity is a CNC router. It is used for precision-carving of wood, acrylic, soft metals and other materials. Onefinity generously discounted this unit through a Makerspace support program they offered to Hacksburg. Hacksburg paired the router with a powerful, 24,000 RPM water-cooled cutting motor. | ||

A CNC router processes "G-code" to tell it where in X,Y,Z space to go, how fast, and in what order. The essence of the process is to first create a model or design (CAD, STL, Thingiverse, Inkscape), then convert that design into G-code. The G-code is transfered to the router controller on a thumb drive, and the router controller executes that code to completion. | |||

[[File:Onefinity Motor.JPEG|320px|thumb|Hacksburg's Onefinity spindle and Y axis]] | [[File:Onefinity Motor.JPEG|320px|thumb|Hacksburg's Onefinity spindle and Y axis]] | ||

| Line 5: | Line 6: | ||

[https://www.onefinitycnc.com/product-page/original-series-woodworker-32-x32-cut-area Onefinity website original model, 32"x32" workspace] | [https://www.onefinitycnc.com/product-page/original-series-woodworker-32-x32-cut-area Onefinity website original model, 32"x32" workspace] | ||

[ | [[File:Onefinity Video thumb.png|thumb|center|[https://youtu.be/DcBWTpXAgfE| 20 second video of Onefinity running]]] | ||

== Safety == | == Safety == | ||

| Line 43: | Line 44: | ||

** Fusion 360 (hobby/education license available) | ** Fusion 360 (hobby/education license available) | ||

== Instructions CNC Router Tutorial ( | == Instructions CNC Router Tutorial (June, 2025) == | ||

You can use other resources to generate g-code. Use LinuxCNC or other simple gcode<br> | You can use other resources to generate g-code. Use LinuxCNC or other simple gcode<br> | ||

* Max F400 in/min for rapid 10,000 mm/min | * Max F400 in/min for rapid 10,000 mm/min | ||

* Max cut around 100 in/min 2500 mm/min | * Max cut around 100 in/min 2500 mm/min | ||

* Spindle speed 24000 rpm! | * Spindle speed 24000 rpm! | ||

* Use gcode M3 for spindle on. Delay for spindle acceleration with | * Use gcode M3 for spindle on. Delay for spindle acceleration with: | ||

''S24000 M3 | |||

G4 P8 ‘ dwell for 8 sec'' | |||

* At the | * At the end of your file, Use gcode: | ||

''M5 ‘to turn off spindle'' | |||

Please have someone check your code first until you're very comfortable with this machine!<br> | Please have someone check your code first until you're very comfortable with this machine!<br> | ||

| Line 58: | Line 59: | ||

Note that this file uses metric for X,Y,Z and feedrates (mm/min)<br> | Note that this file uses metric for X,Y,Z and feedrates (mm/min)<br> | ||

===Code Example=== | ===Code Example. Units in millimeters === | ||

# G17 G21 G40 G49 G94 | # G17 G21 G40 G49 G94 | ||

# G0 X0.000 Y0.000 Z6.000 | # G0 X0.000 Y0.000 Z6.000 | ||

| Line 92: | Line 93: | ||

* Air compressor on | * Air compressor on | ||

* Air valve (red) on | * Air valve (red) on | ||

* Controller on. - black box silver button | * Controller on. - black box, silver button | ||

* Home? Clear the edges of debris and tools to allow full motion range! | * Home? Clear the edges of debris and tools to allow full motion range! | ||

* Jog with Xbox controller | * Jog with Xbox controller | ||

| Line 105: | Line 106: | ||

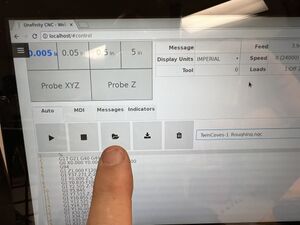

[[File:Program List.jpg|thumb|center|Find the warmup program used for the Onefinity spindle]] | [[File:Program List.jpg|thumb|center|Find the warmup program used for the Onefinity spindle]] | ||

** Clear the spindle, then hit play. Caution: it’s quiet! 8 minutes, then it stops | ** Clear the spindle, then hit play. Caution: it’s quiet! 8 minutes, then it stops | ||

* See progress on the touch screen | ** See progress on the touch screen | ||

* Check motor housing for shake, heat. Should be cool to touch, else the bearings are first suspect | ** Check motor housing for shake, heat. Should be cool to touch, else the bearings are first suspect | ||

** Warmup.ngc only needs to be run once at the start of the day’s machining - good for 24 hours | |||

* Wiggle-check workpiece. | * Wiggle-check workpiece. | ||

* Remove dust shoe to layout workpiece zero | * Remove dust shoe to layout workpiece zero | ||

| Line 159: | Line 161: | ||

* Turn off controller | * Turn off controller | ||

* Clean up everything | * Clean up everything | ||

=== Notes on making a long run === | |||

For the size and speed of the Onefinity, it’s certainly possible to do long, complex cuts! A few notes about the process: | |||

* Any long-running cuts should be preceded by a practice cut - don’t let your first run of the Onefinity be an all-day attempt. Gain some skills and train-up before going on a marathon! | |||

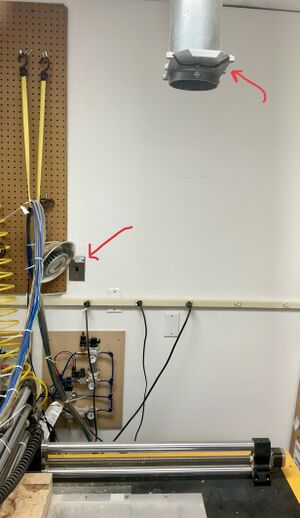

* In addition to the vacuum system, longer cuts require additional room ventilation. There are ceiling-mounted vents in the wood shop. Slide open the one above the Onefinity (climbing and/or step stool needed), and turn on the “light switch” just above the air-control station (see photo). Don’t forget to shut it back down at the end. | |||

[[File:Ceiling Vent and Switch.jpg|thumb|center|Ceiling vent and switch ]] | |||

* There is an air-quality monitor near the main door. The dust & smells you create DO permeate through the building. When in doubt, open the ceiling vents. | |||

[[File:Air Quality monitor.jpg|thumb|center|A digital air quality monitor tracks parts per million within the air. Located near the main shop door]] | |||

* Pay extra attention at the end of your cut to clean ALL around the Onefinity, the floor surrounding it, and the computer/control equipment. Dust/shavings get everywhere! | |||

* Rough cut then Finish cut! Divide your work into a rough cut with a large, material-removal bit, perhaps 60% step-over. Then build a finish cut with a fine detail bit, with a step-over in the range of 25%. | |||

* Other: watch the dust collector fullness level. Check the router-head’s case temperature (by touch) for overheating. Pay attention to your dust collection and potential interference with the shoe/brush. Watch for potential collision from the shoe / brush support arms. | |||

* Example: In the photo below, the workpiece was cut up to 2.25” deep in 2.75” pine, 12”x31”. Rough cut was with a 3/8”, 3-blade cutter for a 4-hour cut, planned for 1mm material remaining. The rough—cut planning involved layers of 6mm (1/4”) until final depth. After 3/4” of depth, the code was paused, and the dust shoe was removed since the tool-head plunge began to get close to the shoe exterior. From then on, the dust vacuum had to be held manually. Once complete, the machine was shut-down, cleaned up and left overnight (or two). The finish cut was a 1/16” taper bit, 30% step over, with no dust shoe. The vacuum/dust system was only needed every 4 to 10 passes, along with some air-hose bursts, to keep the workspace clean. The ceiling vent was still used for this work, since it was fine particles and long-duration. [Inspiration was Touch Terrain website, with a terrain model based around Claytor Lake] | |||

[[File:Finish Cut Touch Terrain model.jpg|thumb|center|Carving a large Touch Terrain model, early in the finish cut]] | |||

Latest revision as of 14:09, 7 July 2025

The Onefinity is a CNC router. It is used for precision-carving of wood, acrylic, soft metals and other materials. Onefinity generously discounted this unit through a Makerspace support program they offered to Hacksburg. Hacksburg paired the router with a powerful, 24,000 RPM water-cooled cutting motor. A CNC router processes "G-code" to tell it where in X,Y,Z space to go, how fast, and in what order. The essence of the process is to first create a model or design (CAD, STL, Thingiverse, Inkscape), then convert that design into G-code. The G-code is transfered to the router controller on a thumb drive, and the router controller executes that code to completion.

Onefinity website original model, 32"x32" workspace

Safety

You must be properly trained before using this machine. It uses a high speed cutting head that can cause serious injuries and a powerful motors that can damage metal, wood and especially humans! It also produces dust and that can be respiratory hazards, and cut chips that can be an eye or cut hazard. If at any time you feel something is wrong or unsafe, stop the machine. Your safety is more important than what you are working on.

Specifications

Original Series Woodworker Package Includes:

- Woodworker Cutting Area: 32 1/8"(X) x 32 1/8"(Y) x 5 1/4"(Z)

- Z-16 Z slider with 133mm travel

- BB Buildbotics controller

- Open Loop Nema 23 Stepper Motors on X,Z, Y1 and Y2 axis

- 1610 Ball Screw on X and Y Axis (Travel Per Revolution is 10mm)

- 1610 Ball Screw on Z axis (Travel Per Revolution is 4mm)

- Integrated sensorless stall homing

- Smart CNC controller with built in software allowing for operation without a computer.

- 8-inch high-definition industrial capacitive touch LED screen.

- Rigid, high precision, hardened steel, linear motion Shafts.

- Precision ball screws on all axis.

- Conveniently located Emergency Stop.

- Rapids at 400 Inches Per Minute (IPM).

- Wi-Fi enabled.

- 4th Axis Rotary Plug & Play Support

- Plug and play XYZ Probe Support

- Plug and play Laser support

- Joypad support makes jogging and positioning your CNC a breeze

- Patent Pending Micro Tramming.

- Quick and easy setup - start carving in under an hour.

- Open ended front to back allowing for 'tiling' (carving pieces longer than the cutting area)

- User friendly design.

- A large “how to” library with a very helpful and supportive community.

- Compatible with all major CAD software including Vectric, Carveco, and Fusion 360

- CNC Software to generate G-gcode:

- Instructable for web-based CNC

- Deskproto (hobby license available)

- Fusion 360 (hobby/education license available)

Instructions CNC Router Tutorial (June, 2025)

You can use other resources to generate g-code. Use LinuxCNC or other simple gcode

- Max F400 in/min for rapid 10,000 mm/min

- Max cut around 100 in/min 2500 mm/min

- Spindle speed 24000 rpm!

- Use gcode M3 for spindle on. Delay for spindle acceleration with:

S24000 M3 G4 P8 ‘ dwell for 8 sec

- At the end of your file, Use gcode:

M5 ‘to turn off spindle

Please have someone check your code first until you're very comfortable with this machine!

Note that this file uses metric for X,Y,Z and feedrates (mm/min)

Code Example. Units in millimeters

- G17 G21 G40 G49 G94

- G0 X0.000 Y0.000 Z6.000

- S24000 M3 'set speed and turn on spindle

- G4 P8 'allow 8 seconds to spin up

- G94

- G1 Z1.000 F1200 'move to height at 1200 mm/min

- G1 Y37.271 Z-2.261 F1284 'plunge into work

- G1 Y0.000 Z-5.522

- 'lots of other G1 commands, or skip "G1" and just give X, Y, Z coordinates since G1 is assumed

- G1 Y64.295

- G1 X65.965

- G0 Z6.000 'return to clearance height

- M5 'turn off spindle

- M30 'end of the program

Workpiece fixturing

Ensure your workpiece won't move!

As we improve the aluminum hold-down fixture, we can use screw-in clamps

Always use a spoiler-board: sacrificial wood or acrylic in case you cut too deep

Ensure the workpiece is flat by using the belt sander. Test for wobble before mounting.

Attach workpiece to spoilerboard with double-sided carpet tape (white roll in shop)

- Ok to shut ball-valve while fixturing

- For carpet tape, weight down workpiece a few minutes while doing the other start-up procedures

Machine Tool Power Up

- Air compressor on

- Air valve (red) on

- Controller on. - black box, silver button

- Home? Clear the edges of debris and tools to allow full motion range!

- Jog with Xbox controller

- Green=slow, red= medium Yellow= fast.

- Warm up procedure:

- Air back on

- Power for 220 VFD: behind crates, bottom of the metal shelf

- Radiator: beige box on floor, top right rocker.

- Spindle will ramp up to 24k. Load & run Warmup.ngc on screen scroll list

- Clear the spindle, then hit play. Caution: it’s quiet! 8 minutes, then it stops

- See progress on the touch screen

- Check motor housing for shake, heat. Should be cool to touch, else the bearings are first suspect

- Warmup.ngc only needs to be run once at the start of the day’s machining - good for 24 hours

- Wiggle-check workpiece.

- Remove dust shoe to layout workpiece zero

- X0 Y0 according to your Gcode process. Convention is to have (0,0) at the close-left side, so that X+ is to the right, and Y+ is away from you.

- Set the tool in collet (also see the change tool process details in the section below this one)

- Hold tool, press pedal until completely out, release pedal

- Leave pedal in the location where it is tough to accidentally hit

- Hold tool collet just under, press pedal to air clean a few seconds, push tool up and release pedal to catch collet. Test spin with fingers and pull by hand to ensure seating.

- X zero: Machine is actually in metric mode for input values, but displays “inches”. Or “in”. It wakes up in metric mode. So input a 1/4” as 6.35.

- Y zero: same process.

- Replace dust shoe- magnet catch. Adjust dust feet with wing nuts for brush to contact work surface.

- Z zero: you can use feeler guage or paper to position the cutter 0.005" above the material. Negative Z is into the material, 0 is at the top.

- Load your guide by inserting thumb drive in back of controller

- Press black folder and find thumb drive, folder and file. Then find file in drop down list

- Hook in dust hose

- Check everything!

- Turn on dust collection, gate open for your hose

Run the Gcode!

- Play button becomes the pause button. Hover your finger a while to be ready for any weirdness.

- Issue with job: screen pause

- Issue with machine: red stop button located on back of controller

- See “remaining” indicator for job time. Progress bar is by line number

- Scroll display to x,y,x readout.

- With the whine of the spindle plus the vacuum, wear hearing protection

- Never leave tool running unattended. Stay right there for the duration of your job.

- If you need to use the bathroom, tag-up with a friend, or pause the cut!

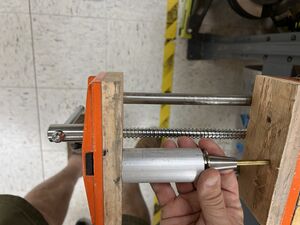

Change a tool

Changing a tool manually involves releasing the collet, explained in the Power Up procedure

Once you have the collet, use the collet wrenches to open the jaws

Sometimes, the tool bit will not release from the collet

Use the Tool holder bit extractor, stored in a ziplock bag

Once the top collet nut has been removed, place the collet in the aluminum pipe, and the brass rod into the collet, resting on the captured bit. Place the assembly in the large woodworking vise located mid-shop. Slowly turn the vise to gently release the bit. Have your hand ready to catch the assembly when the bit releases!

Shut down process

- At job end, use dust collector to clean area, then turn off the dust collector.

- If you take out your tool, leave a tool in the spindle to keep it clean and spring-catch engaged

- Home the tool to back left to leave table open

- Power off the air ball valve, then the air compressor

- Turn off the radiator

- Turn off the 220 Volt VFD

- Turn off controller

- Clean up everything

Notes on making a long run

For the size and speed of the Onefinity, it’s certainly possible to do long, complex cuts! A few notes about the process:

- Any long-running cuts should be preceded by a practice cut - don’t let your first run of the Onefinity be an all-day attempt. Gain some skills and train-up before going on a marathon!

- In addition to the vacuum system, longer cuts require additional room ventilation. There are ceiling-mounted vents in the wood shop. Slide open the one above the Onefinity (climbing and/or step stool needed), and turn on the “light switch” just above the air-control station (see photo). Don’t forget to shut it back down at the end.

- There is an air-quality monitor near the main door. The dust & smells you create DO permeate through the building. When in doubt, open the ceiling vents.

- Pay extra attention at the end of your cut to clean ALL around the Onefinity, the floor surrounding it, and the computer/control equipment. Dust/shavings get everywhere!

- Rough cut then Finish cut! Divide your work into a rough cut with a large, material-removal bit, perhaps 60% step-over. Then build a finish cut with a fine detail bit, with a step-over in the range of 25%.

- Other: watch the dust collector fullness level. Check the router-head’s case temperature (by touch) for overheating. Pay attention to your dust collection and potential interference with the shoe/brush. Watch for potential collision from the shoe / brush support arms.

- Example: In the photo below, the workpiece was cut up to 2.25” deep in 2.75” pine, 12”x31”. Rough cut was with a 3/8”, 3-blade cutter for a 4-hour cut, planned for 1mm material remaining. The rough—cut planning involved layers of 6mm (1/4”) until final depth. After 3/4” of depth, the code was paused, and the dust shoe was removed since the tool-head plunge began to get close to the shoe exterior. From then on, the dust vacuum had to be held manually. Once complete, the machine was shut-down, cleaned up and left overnight (or two). The finish cut was a 1/16” taper bit, 30% step over, with no dust shoe. The vacuum/dust system was only needed every 4 to 10 passes, along with some air-hose bursts, to keep the workspace clean. The ceiling vent was still used for this work, since it was fine particles and long-duration. [Inspiration was Touch Terrain website, with a terrain model based around Claytor Lake]